PB-830A & HG-2504C Hydraulic Panbrake & Guillotine Package Deal Panbrake: 2500 x 4mm - Guillotine: 2

PB-830A & HG-2504C Hydraulic Panbrake & Guillotine Package Deal Panbrake: 2500 x 4mm - Guillotine: 2 : $31,950 AUD ($35,145 Inc. GST)

METALMASTER PB-830A & HG-2504C Hydraulic Panbrake & Guillotine Package Deal Panbrake: 2500 x 4mm - Guillotine: 2500 x 4mm Mild Steel Capacities

CALL NOW AND DO A DEAL! ADD THIS ASSET TO YOUR WORKSHOP

WE OFFER MACHINERY SOLUTIONS AT AFFORDABLE PRICES.

Order Code: K063

PANBRAKE PB-830A - Hydraulic NC Panbrake:

2500mm x 4mm bending capacity

NC-89 digital single angle programmable control for angles from 0-125º

Auto cycle: after clamping bottom beam will bend to pre-set angle and return, head unclamps to set position

Quick action rapid head adjustment to optimise bend radius on 1-4mm material thickness

Heavy duty steel fabricated construction

Roving foot pedal incorporates control panel for maximum flexibility

High quality components ensure reliable performance for years of continuous operation

NC-89 controlled opening height adjustment

NC-89 controlled dwell timer ensures consistent bending angle

Extended fingers allows bending of pans or boxes to a depth of 205mm

Includes an adjustable rear manual backgauge, also adjustable for tapered material

Mild steel capacity is rated on hot rolled material with 250MPA

Pre-Commissioning:

1. Panbrake bender is run & tested prior delivery

2. Hydraulic oil is included with machine

GUILLOTINE HG-2504C - Hydraulic Swing Beam Guillotine:

2500mm x 4mm cutting capacity

5.5kW / 7.5hp 415V motor

Estun E21S Controller

Mobile foot pedal for "hands free operation"

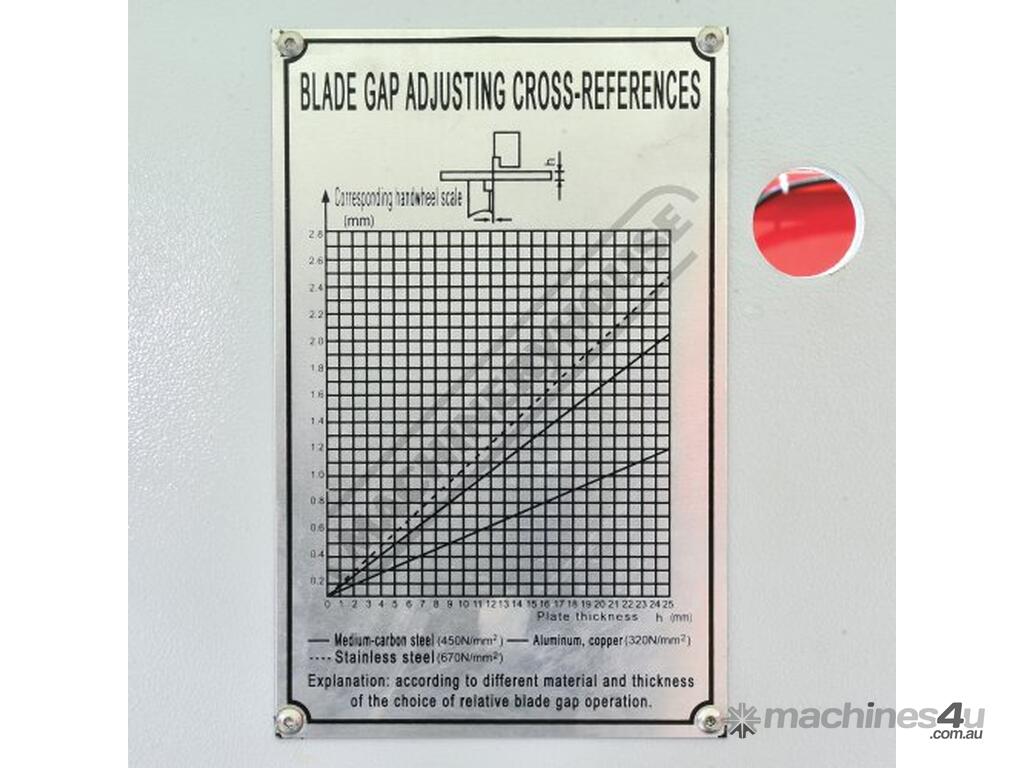

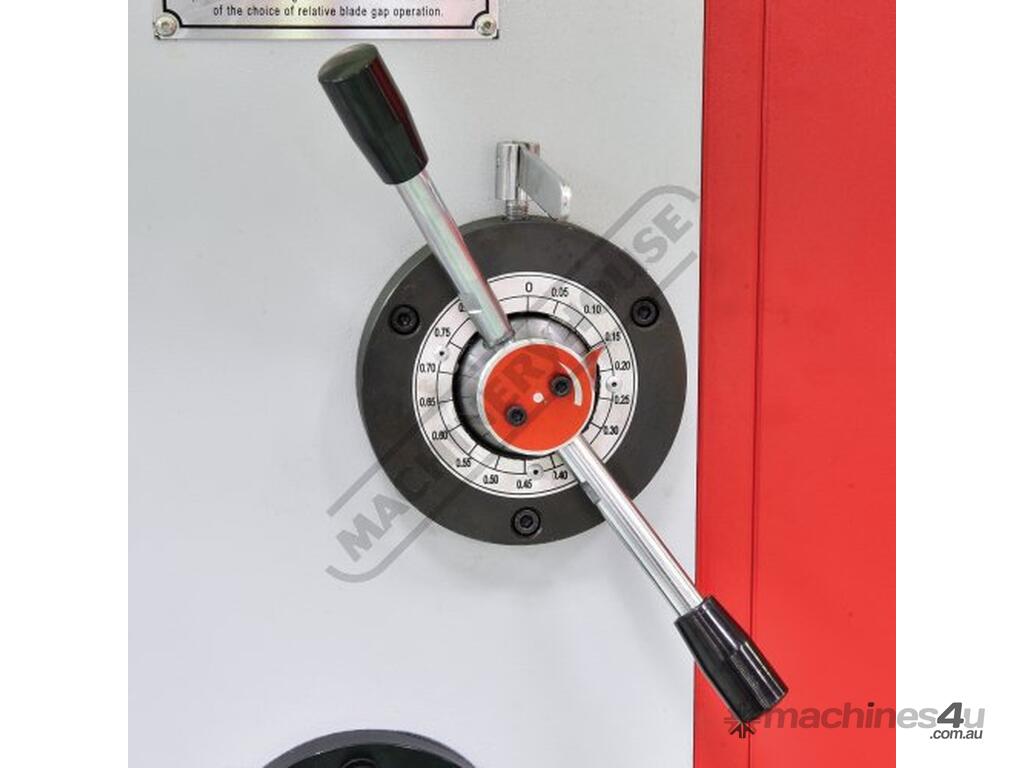

Single point rapid blade gap adjustment

High quality blades suitable for cutting stainless steel

Programmable backgauge with 800mm travel

Automatic backgauge retract function during cutting

Swing away backgauge function for cutting long sheets

Individual hydraulic clamp hold downs with nylon pads

LED Shadow line lighting

Transfer balls on table

Support arms and squaring arm

Stroke counter and short stroke adjustment

Sliding material chute, easily allowing operator to retrieve cut pieces

Safety light curtains on rear guarding

Compliant AS/NZS 4024.1 – 2019 Safety of Machinery Series

METALMASTER Quality Guillotines provide precision shearing capabilities, The Guillotine frames are constructed from rolled, stress relieved solid steel to prevent distortion during the shearing process under extreme continuous loads.

METALMASTER Guillotines are produced in a quality controlled production environment and therefore are able to be manufactured cost effectively, resulting in affordable pricing, representing value for money and a quicker return on investment.

The heavy duty swing beam design features a fixed rake blade specifically developed for shearing material from mild steel through to stainless steel. The blades are made from high tensile tool steel and also provide high resistance to Impact, wear & corrosion.

Estun E21S controller stores up to 40 unique programs with 25 automatic progressive cutting steps in each individual program, assuring production accuracy & repeatability every time

Programmable backgauge system, simply enter the desired measurement into the Estun E21S controller or the program and press go, the backgauge then will move quickly into the position you have requested.

Rapid blade gap adjustment ensuring quick & accurate alteration of blade gap between material changes.

Automated hydraulic material clamping system designed with individual hold downs along the length of the machine, The individual hold downs are fitted with nylon inserts to protect the material from indentation when clamping.

Transfer balls inserted into work table allowing larger sheets to be easily positioned to the cut position and squaring arm.

Top shearing blade has two (2) cutting edges allowing blade rotation.

Bottom shearing blade has four (4) cutting edges allowing multiple blade rotations.

The entire steel plate structure of the main frame has been specially prepared to ensure maximum penetration during the welding process. In addition to this the cutting beam has been stress relieved eliminating any distortion after manufacturing.

Shadow line lighting has been incorporated into the machine frame providing a clear cutting line on the work piece and enabling scribed or marked material to be cut with simplicity as required.

A heavy duty squaring arm fitted with a graduated rule allows the operator to quickly cut the required size from the front of machine. The squaring arm also assists to align the material square to the cutting blades.

Sliding rear material chute so scrap material does not build up in the rear of the machine.

A safety system with photo electric rear guards are fitted to the rear steel side gates ensuring that the machine will be disabled if a person enters rear of machine when in use.

Mild steel capacity is rated on hot rolled material with 250MPA

Pre-Commissioning:

1. Guillotine is run & tested prior delivery

2. Hydraulic oil is included with machine.

Specifications:

ORDER CODE: K063

MODEL: PB-830A & HG-2504C Package

Controller Type: NC-89

Controller Type: Single Program

Bending Length (mm): 2500

Mild Steel Capacity (mm): 4

Stainless Steel Capacity (mm): 2

Material Clamping Type: Hydraulic Clamp

Material Bending Type: Hydraulic Bend

Bending Angle Indicator (deg): 0-125º

Backgauge Travel (mm): 1000

Motor (kW / hp): 5.5 / 7.5

Voltage / Amperage (V / amp): 415

Floor Space (L x W x H) (mm): ~

Nett Weight (kg): 5826

To Purchase Online Please Visit The Machineryhouse Website & Search For 'K063'

Visit us in-store at:

Sydney - Unit 1, 2 Windsor Road, Northmead NSW 2152

Melbourne - 4 Abbotts Road, Dandenong South VIC 3175

Brisbane - 625 Boundary Rd, Coopers Plains QLD 4108

Perth - 11 Valentine Street, Kewdale WA 6105

Adelaide - Unit 11/20 Cheltenham Parade, Woodville SA 5011

Facebook

Facebook Twitter

Twitter

Email

Email

Print

Print