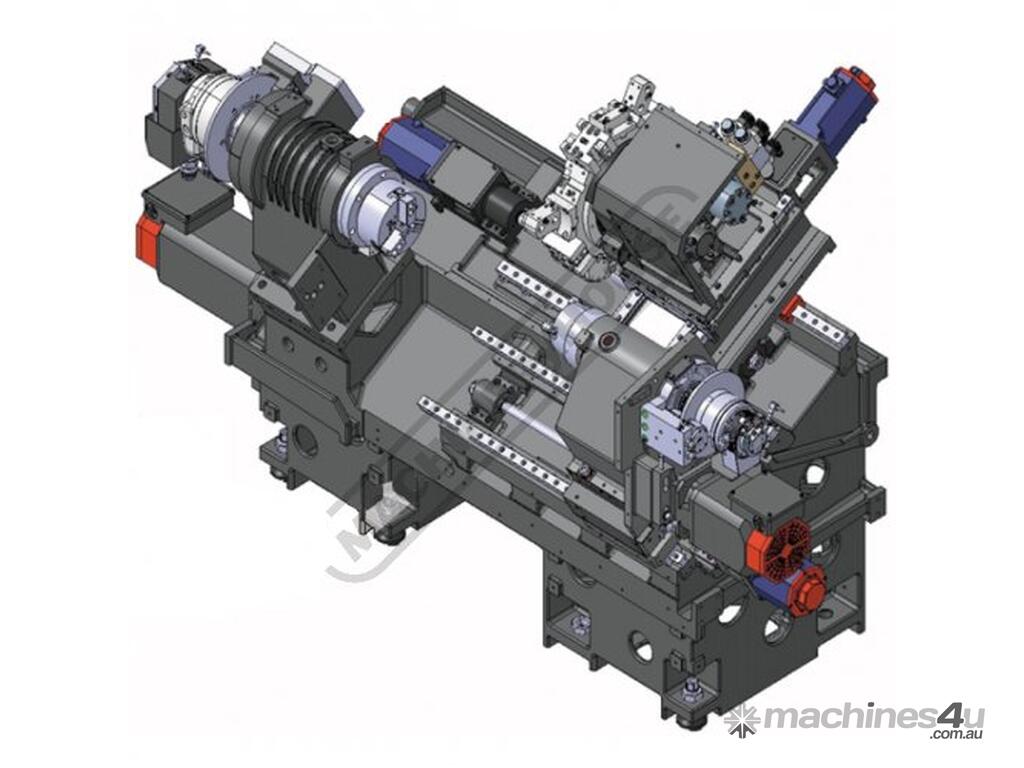

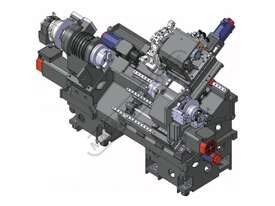

LYNX 2100LSYB CNC Turning Centre Y Axis & Sub Spindle

LYNX 2100LSYB CNC Turning Centre Y Axis & Sub Spindle : Ask for Price

DN SOLUTIONS LYNX 2100LSYB CNC Turning Centre Y Axis & Sub Spindle

CALL NOW AND DO A DEAL! ADD THIS ASSET TO YOUR WORKSHOP

WE OFFER MACHINERY SOLUTIONS AT AFFORDABLE PRICES.

Order Code: L7064

Overview

Basic Specifications

- 600mm Swing Over Bed

- 400mm Swing Over Saddle

- 510mm Turning Length

- 300mm Turning Ø

- 105mm (±52.5mm) Y Axis Travel

- 360deg (0.001deg Resolution) C Axes, Main & Sub Spindles

- 150kg Main Spindle Capacity

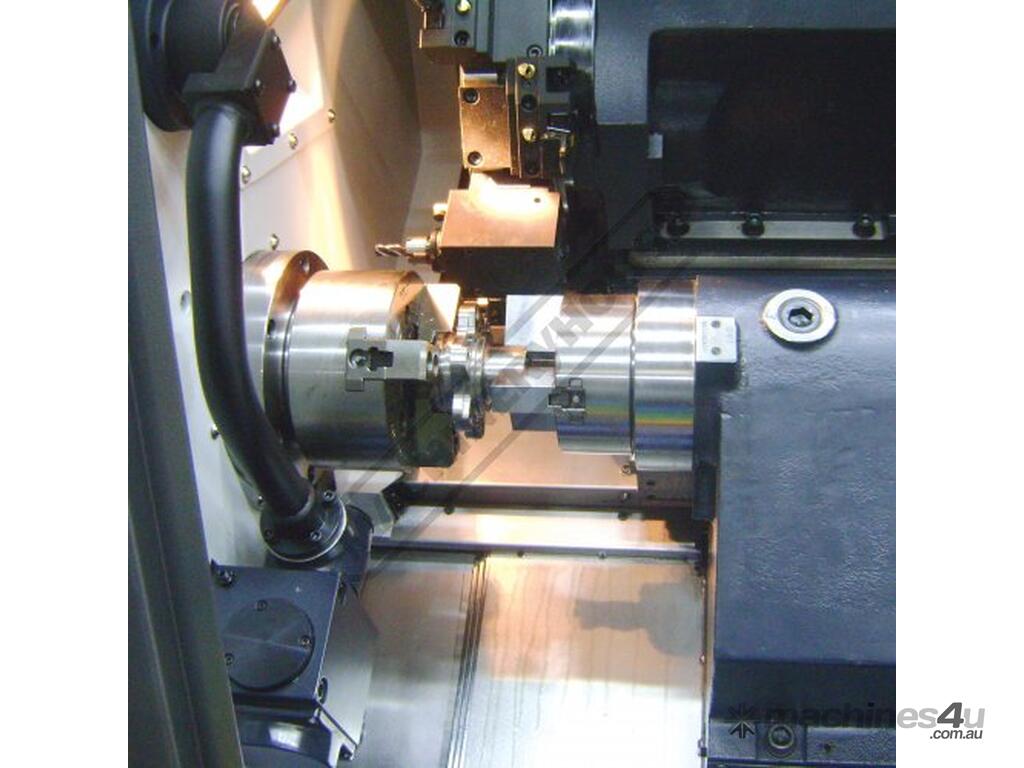

Main Spindle

- 65mm Bar Capacity

- 200mm Ø Hydraulic Chuck

- 4500RPM Spindle Speed

- 15kW Spindle Power

- 169Nm Spindle Torque

Sub Spindle

- 35mm Bar Capacity

- 127mm Ø Hydraulic Chuck

- 6000RPM Spindle Speed

- 5.5kW Spindle Power

- 46Nm Spindle Torque

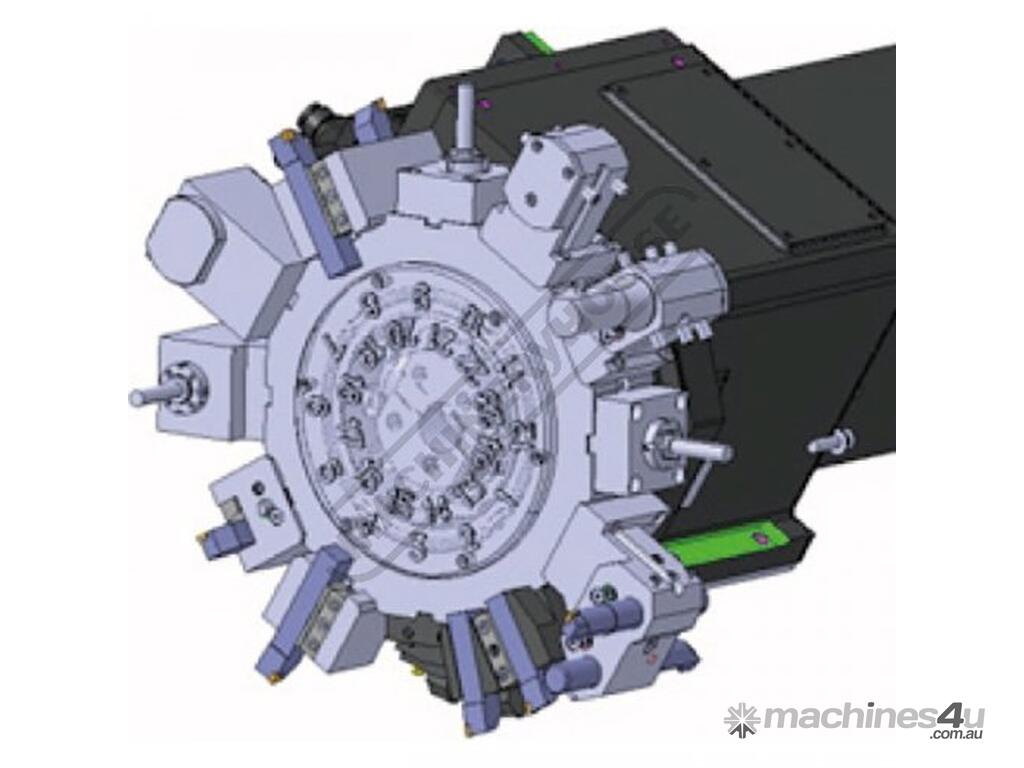

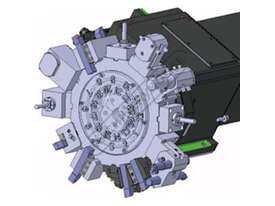

Turret

- BMT 45 Tool Mounting

- 6000RPM Live Tool Speed

- 3.7kW Live Tool Power

- 23.5Nm Live Tool Torque

- 24 Position / 12 Station Turret

- 20mm Square / 32 & 20mm Ø Tool Capacity

- ER20 Live Tool Collet Size

- Eppinger Preci-Flex Tooling System

CNC Control

- Doosan Fanuc I Series (0i-Plus) CNC Controller

- 15" Colour LCD Monitor

- Rigid-synchronised tapping

- Custom Macro B

- Ethernet Interface

- RS232 Interface

- USB & PCMCIA Memory Card Slot

- Doosan Ezi Guide "I" Conversational software:

- Graphical Turning Cycles

- Graphical Milling Cycles

- Full 3D Graphical Simulation

- Onboard G & M code assistance

- + more

Standard Equipment - Included

- 3 Jaw Hydraulic Power Chucks

- Grease Cartridge Auto Lubrication System

- Chuck Cleaning Air Blast

- Eppinger rotary tool holders with Preci-Flex adapter set

- Coolant supply equipment

- Foot switches

- Transformer

- Full enclosure chip and coolant shield with front door interlock

- Hand tool kit

- Automatic lubrication equipment

- Comprehensive manuals incorporating, Operation, Maintenance, Programming, Spare Parts Diagrams, Hydraulic Schematics, Electrical Schematics and Ladder Diagrams.

- Safety name plates / tags where required

- Risk assessment

- Work light

Optional Equipment Included

- Chuck open close confirmation proximity switches

- Chip Conveyor (Side Discharge, Hinged Belt)

- Auto Tool Setter (Hydraulically operated)

- 7 Bar High Pressure Coolant

- Barfeed Interface

- Parts Catcher with Parts Conveyor

- Sub Spindle Work Ejector

- Chuck Cleaning Air Blast

- Auto Power Off Function

Standard Turret Tool Holder Package Included

- 1 x OD Tool Holder Main (R & L)

- 1 x DBL OD Tool Holder Main/Sub (R & L)

- 1 x DBL OD Tool Holder Main (R & L)

- 1 x DBL OD Tool Holder Sub (R & L)

- 1 x ID Tool Holder Main

- 1 x Double ID Tool Holder Sub

- 1 x Triple ID Tool Holder

- 1 x Face Tool Holder Main (R & L)

- 1 x Cut Off Tool Holder

- 1 x U Drill Cap Main

- 1 x U Drill Cap Sub

- 2 x Straight Milling Unit

- 1 x Angular Milling Unit

- 1 x Offset Angular Milling Unit

- 1 x Eppinger "Preci-Flex" Kit

- 1 x Boring Sleeve Kit Main

- 1 x Boring Sleeves Kit Sub

- 1 x U Drill Sleeve Kit

- 1 x ER 20 Milling Collet Set

- 1 x Hard & Soft Jaws Main and Sub

Local Service and Support

- Commissioning & Testing Included

- Comprehensive Operator Training Included

- Hare and Forbes In House Service And Applications Staff

- Ongoing Support For Life Of The Machine

Features:

Doosan Machine Tools changes its name to DN Solutions

Read more at:

Specifications:

ORDER CODE: L7064

MODEL: LYNX 2100LSYB

Swing (mm): 600

Max Turning Diameter (mm): 300

Turning Length (mm): 510

Chuck Diameter (mm): 200

Bar Diameter Capacity (mm): 65

Tool Stations (No.): 12/24

Spindle Speed (rpm): 4500

Spindle Motor (kW): 15

Guideways: LMG

Control: Doosan Fanuc I Series (0i-Plus)

Programming: EZI Guide I Conversational

C Axes Resolution (deg): 0.001

Milling Speed (rpm): 6000

Milling Collets: ER20

Sub Chuck Diameter (mm): 127

Y Axis Travel (mm): 105 (±52.5)

To Purchase Online Please Visit The Machineryhouse Website & Search For 'L7064'

Visit us in-store at:

Sydney - Unit 1, 2 Windsor Road, Northmead NSW 2152

Melbourne - 4 Abbotts Road, Dandenong South VIC 3175

Brisbane - 625 Boundary Rd, Coopers Plains QLD 4108

Perth - 11 Valentine Street, Kewdale WA 6105

Facebook

Facebook Twitter

Twitter

Email

Email

Print

Print