APHS-31200 Hydraulic CNC Pressbrake 200T x 3100mm, 5 Axis, Delem DA69T Touch Screen Control Includes

APHS-31200 Hydraulic CNC Pressbrake 200T x 3100mm, 5 Axis, Delem DA69T Touch Screen Control Includes : $144,950 AUD ($159,445 Inc. GST)

BAYKAL APHS-31200 Hydraulic CNC Pressbrake 200T x 3100mm, 5 Axis, Delem DA69T Touch Screen Control Includes Programmable X, Y1, Y2, V & R-Axis. CNC Table Crowning & Laser Guarding System

CALL NOW AND DO A DEAL! ADD THIS ASSET TO YOUR WORKSHOP

WE OFFER MACHINERY SOLUTIONS AT AFFORDABLE PRICES.

Order Code: S886G

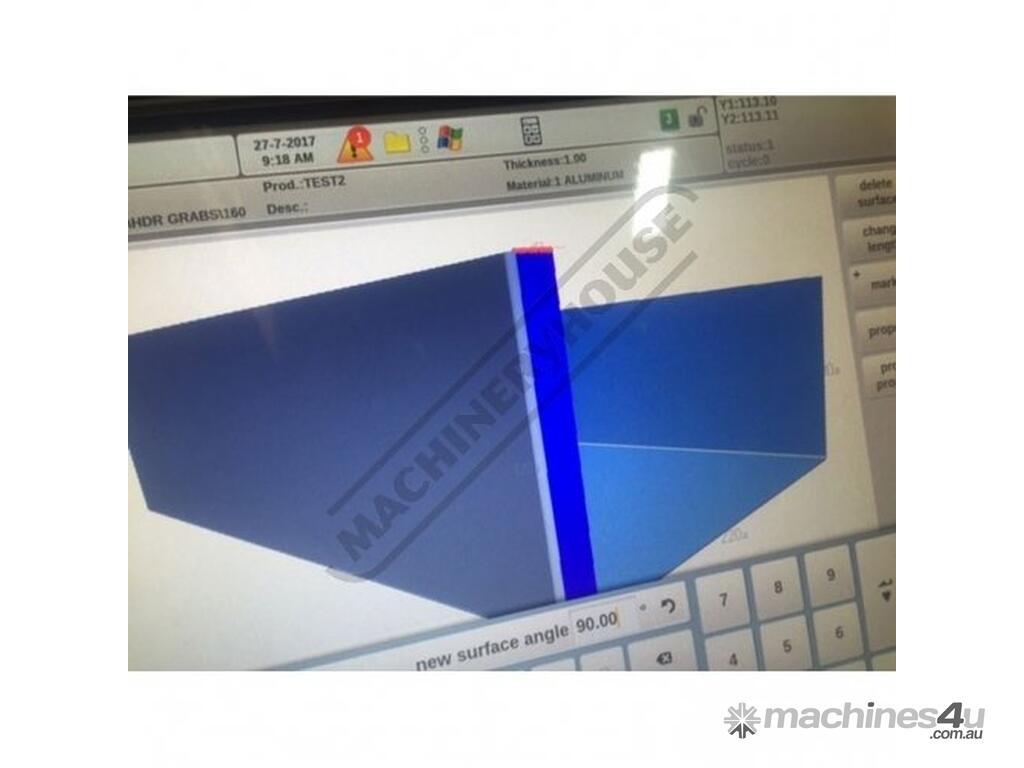

Delem DA-69T CNC CONTROL UNIT

The new generation DA-Touch controls offers an even higher grade of efficiency in programming, operation and control of

today’s press brakes. Ease of use combined with state-of-the-art technology go hand in hand, improving productivity.

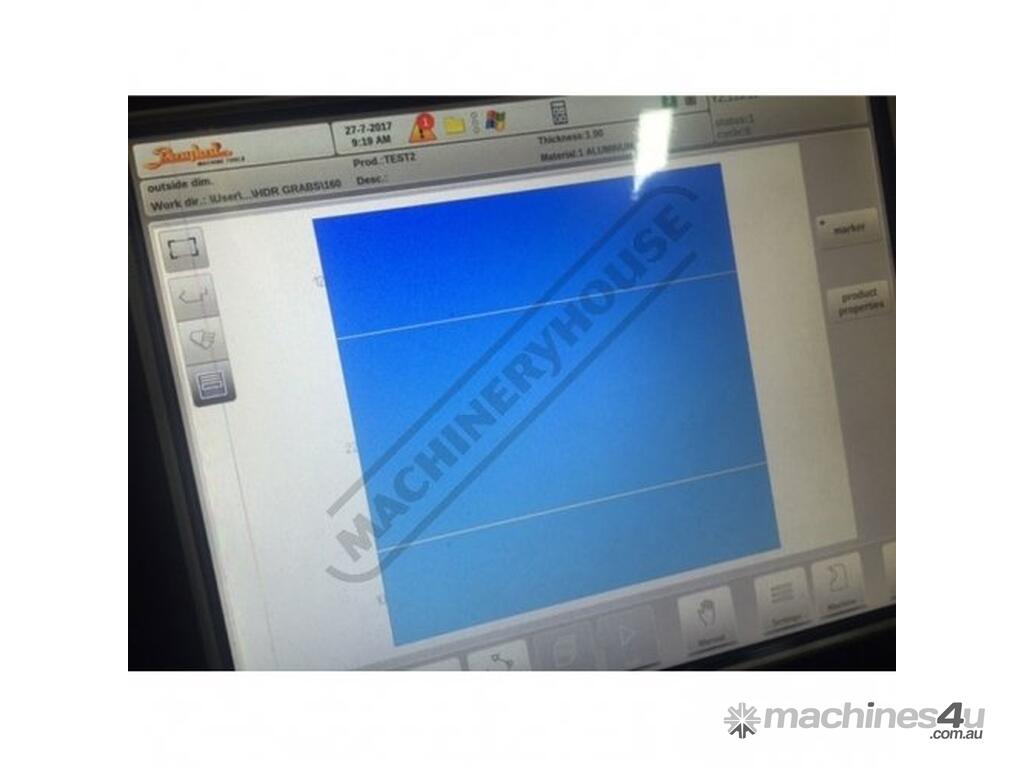

The touch screen gives access to the proven Delem user-interface and enables direct navigation between programming

and production. Functions are directly located where you need them, offering optimised ergonomics throughout the application.

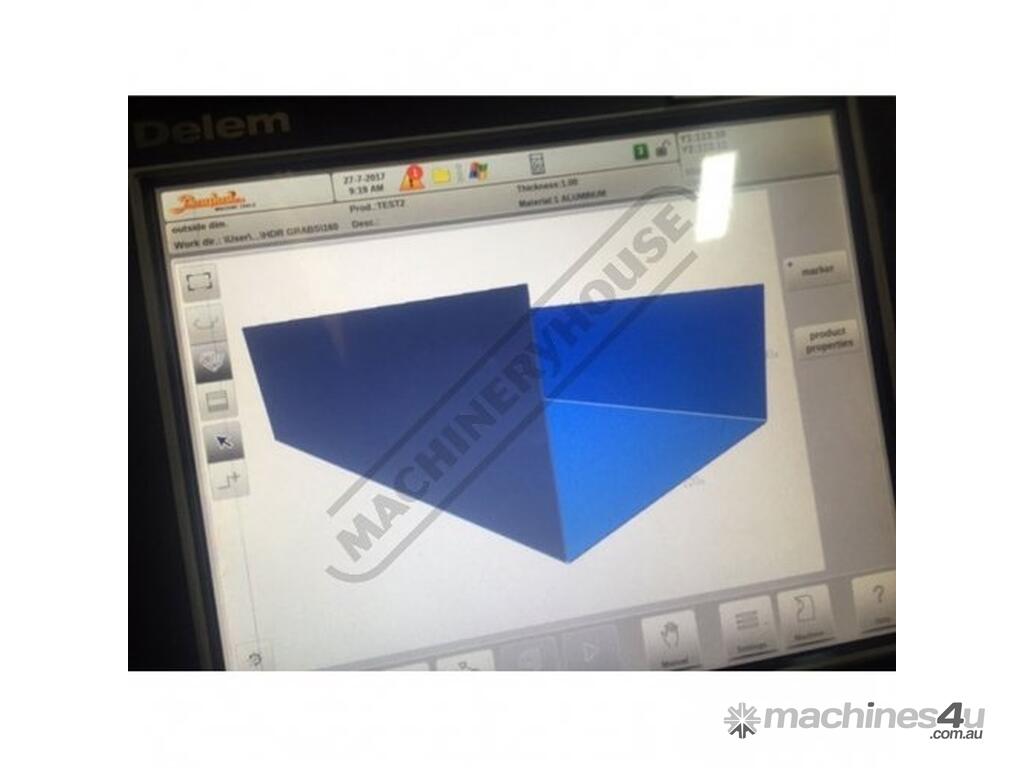

The DA-69T offers 2D as well as 3D programming that includes automatic

bend sequence calculation and collision detection. Full 3D machine set-up with multiple tool stations giving true feedback on the product feasibility and handling.

Highly effective control algorithms optimise the machine cycle and

minimise set-up time. This makes using press brakes easier, more efficient and more versatile then ever.

The OEM-panel located above the screen, reserved for machine functions and OEMapplication switches, is integrated in the design and can be used depending the required application.

3D and 2D graphical touch screen programming mode

3D visualisation in simulation and production

17" high resolution colour TFT

Full Windows application suite

Delem Modusys compatibility (module scalability and adaptivity)

USB, peripheral interfacing

Open system architecture

Sensor bending & correction interface

Features:

Baykal machine frames consist of a monolithic structure with hot rolled steel sheets of Fe 520 welded together. The two housings (shoulders) are obtained from the same sheet to ensure the same elasticity under stress. The ram and table are also obtained from Fe 520 steel sheets and are opportunely dimensioned to avoid deflection

The hydraulic cylinders are manufactured from high resistance steel incorporating chromium plated & ground rods. Completed with lapped pistons to ensure longevity of the hydraulic seals

The hydraulic unit is made by major companies in the field. It consists of electronically controlled proportional valves with independent closed loop control of the two cylinders.

5 CNC Controlled Axis (Y1 Y2 X R V) as standard. Multi Axis available

Full electronic Synchronisation with proportional valve technology.

German manufactured Laser-Safe Guard System mounted at each end of machine ensuring correct interfacing and operator safety whilst in operation. Laser-safe is designed so each guard will slide up or down to allow for many different types and sizes of tooling enabling safety at the appropriate points as required by the Australian standards. Manual height adjustment with scales and lock for easy positioning.

Sliding steel fabricated front sheet supports enabling a wide range of material sizes to be aligned and supported at the correct required width and height. This function is achieved by the precision linear guides mounted on the front apron parallel to the tooling length. This design can also be adjusted vertically to support material with return bends.

Ram positions (Left & Right) are obtained from independent linear encoders whilst monitoring and adjusting proportional valves. This produces a double closed loop system with guaranteed beam positioning of +/- 0.01mm (Y1 and Y2 Axis)

Electronic control of bending parallelism is via the Delem DA-69T CNC Control

Accuracy is further ensured by mounting the linear encoders on a C-frame connected directly to the Bed rather than the side frames. This ensures that deflection of the side frames and uneven loads have no effect on Beam position.

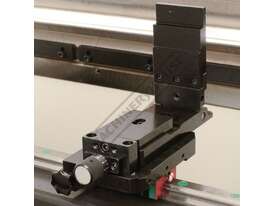

CNC Controlled Back-gauge:- X-Axis stroke 750mm with DC motor mounted on hardened and machined guides translation via spherical recirculating ball screws

Delem DA-69T CNC Control fully programmable with 3D & 2D graphics offline software included

Precision linear scale measurement : HEIDENHAIN or GIVI MISURE

Y1-Y2 - X-R CNC auto crowning table - controlled stroke axes

CNC controlled hardened ballscrew backgauge with X-axis

X axis range = 750mm speed = 350mm/s max.

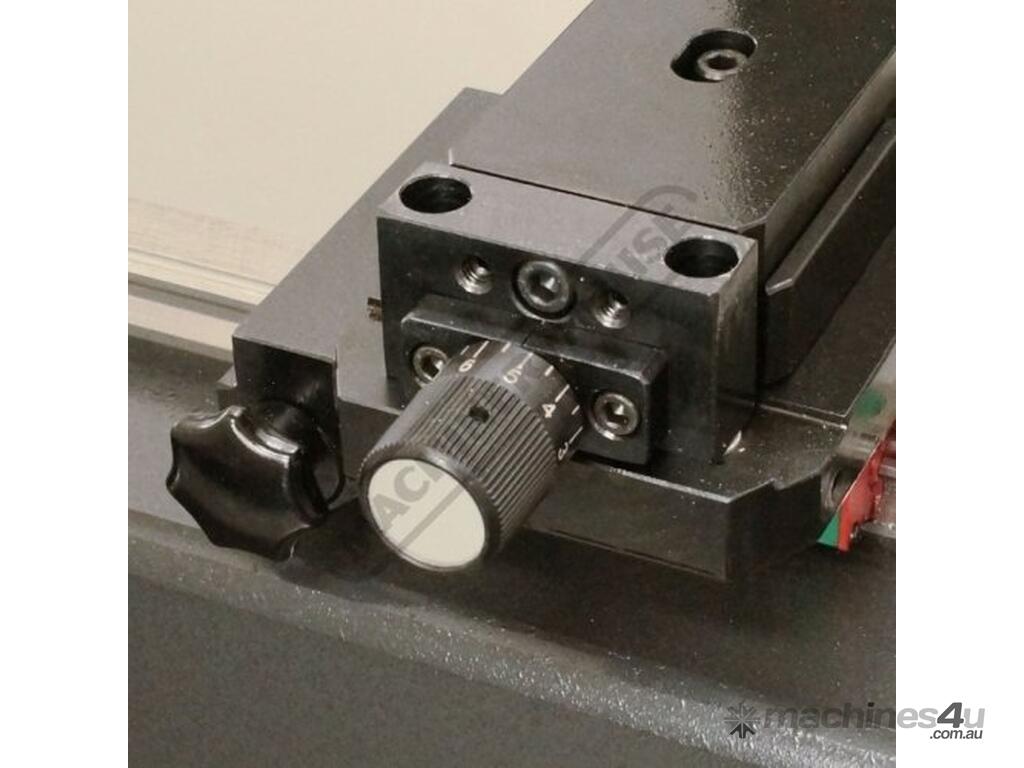

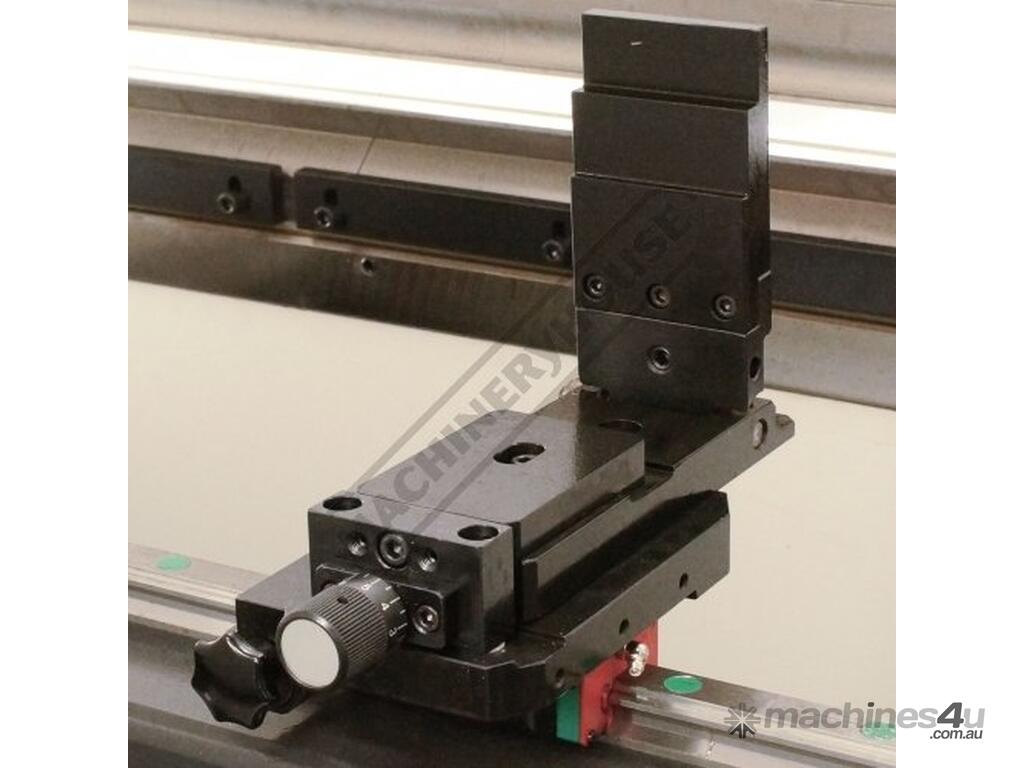

2 micrometric backgauge finger stops with lateral adjustment

Front support arms fully adjustable mounted on linear rails x 2 off easy positioning over the complete working length of the machine

Quality Siemens Electric control switch Gear is used

Pendant control panel centralising all Press-Brake Functions

Foot Pedal Control Emergency stop buttons

2 axis tower type backgauge with AC servo motors

X-R CNC axis

bar length 2400mm ( size 200x150mm )

"X" axes stroke 750mm

"R" axes stroke 160mm

2 micro adjustable fingers with 2D stops sliding all long the bar

Hardening on fingers

All movements on ball screws and ball guides

AC servo brushless motors

"X" axis speed of 350mm/sec

"R" axis speed 240mm/sec

Mechanical accuracy 0.1mm

Hydraulics: Hoerbiger & Parker (German & USA)

Electrics: Siemens or Telemecanique (German or French)

Scales: Misure or Heidenhain (Italian or Dutch)

Tooling: Technostamp or Rolleri (Italian)

Control: Delem DA-69T

PLC: AKAS

Mild steel capacity is rated on hot rolled material with 250MPA

Includes:

- Delem DA-69T 3D & 2D Graphical CNC Control

- Offline graphical 3D software

- Y1-Y2 cylinder axis

- X - R Backguage

- V - table NC auto crowning

- Quick release top tool clamping system

- AKAS Safety laser front guarding system

- Mechanical crowning on top intermediate clamps

Specifications:

ORDER CODE: S886G

MODEL: APHS-31200

Control Unit (Type): DELEM DA69T CNC

Nominal Pressure - Tonnage (Ton): 200

Nominal Pressure - Kilonewtons (kN): 2000

Length of Work Table (mm): 3100

Distance Between Columns (mm): 2550

Throat Depth (mm): 410

Maximum Open Height (mm): 540

Ram Stroke (mm): 260

Machine Axis (No.): 5

Safety Guarding System (Type): Laser System

Ballscrew Backgauge Travel (mm): 750

Leadscrew Backgauge Travel: ~

Table Bed Crowning System (Type): CNC Controlled System

Motor Power (kW / hp): 18.5 / 25

Motor Voltage (V): 415

Floor Space (Includes Front Sheet supports) (mm): ~

Nett Weight (kg): 10000

To Purchase Online Please Visit The Machineryhouse Website & Search For 'S886G'

Visit us in-store at:

Sydney - Unit 1, 2 Windsor Road, Northmead NSW 2152

Melbourne - 4 Abbotts Road, Dandenong South VIC 3175

Brisbane - 625 Boundary Rd, Coopers Plains QLD 4108

Perth - 11 Valentine Street, Kewdale WA 6105

Facebook

Facebook Twitter

Twitter

Email

Email

Print

Print